This is an ambitious project for the Belgian Lab Automation Company MicroTechnix implemented by Softengi AI Team. In essence, it’s a lab system workflow automation & orchestration with the help of which it is possible to complete the whole process of 99% accurate bacteria detection in a lab without human intervention. But it’s curious to tell you more about the very process.

We started the project with the automation of the software program creation, then moved to the automation of the workflow in a lab, and ended with AI/ML automation of the bacteria detection. In the end, we made it possible for any lab employee to manage lab equipment to get 99% accurate results on the bacteria/viruses’ presence in a Petri dish.

Part 1: Automation of the Software Program Creation for the Lab Equipment

Before the digital transformation provided by Softengi, MicroTechnix employees used the list of XML files with a set of commands to launch any process within the lab. Whenever an action from the lab equipment was required, an employee had to actually change the parameters in the code. Each command and function, such as starting the work of a cytomate, could only be initiated with the help of the changes in XML files and the upload of these files into the system.

Naturally, this process would generate a lot of human-made errors, and each error could result in the malfunctioning of the equipment. More than that, the process is time-consuming. We structured and categorized all possible commands into blocks inside a user-friendly graphic interface and made the whole process of program creation intuitive.

Technology used: Python

Result: The first stage of the cooperation resulted in a set of graphic dashboards using which employees could create the programs that launched the laboratory equipment work with zero risks of human errors. The process of programming the equipment with the XML files and writing code was in the past.

Part 2: Kiosk Programming for the Workflow Automation of the Lab

Yet, our client wanted to make the whole process of lab equipment management as easy as possible for all the employees of the company. That is how we came to the creation of the software for kiosks. With kiosks, lab management became accessible to even non-technical specialists of the company who don’t have experience in programming.

Kiosks are essentially user-friendly screens through which users can perform a number of tasks and operations, in our case, manage lab equipment. For MicroTechnix, it was crucial to automate the process of equipment management so that any user could configure all the processes for each Petri dish. Here are several important features of the software system for kiosks:

- There are a number of devices that are included in the whole lab automation system, such as a robotic hand, a cytomate, a photo camera – all these devices must be synchronized to work with Petri dishes and to react appropriately to different information received from the AI system.

- Any user must always know where all the Petri dishes are at each exact moment, what operations are expected, and what results were achieved from the existing Petri dishes.

- Secure access that presupposes several levels of authentication was also required.

- It is important to take into account that the whole story of all the manipulations with each Petri dish has to be recorded so that it is possible to trace all the manipulations in case something goes wrong.

The electronic records created in the process of lab orchestration are maintained according to regulatory requirements contained within the FDA’s 21 CFR Part 11 for US jurisdictions. All this has become possible with the workflow automation system written for kiosks:

Using this simple kiosk, any lab user can launch the whole process of Petri dishes assessment. Here is how the whole process of lab automation and orchestration looks in action:

- Taking a Petri dish;

- Scanning a QR code on the Petri dish;

- Placing a Petri dish under a photo camera;

- Detecting if there are bacteria and viruses according to the predefined parameters with AI;

- Putting a Petri dish into a cytomate;

- Initiating the Response re specific Petri dish.

Part 3: Computer Vision/Machine Learning for Quality Control: Bacteria Detection

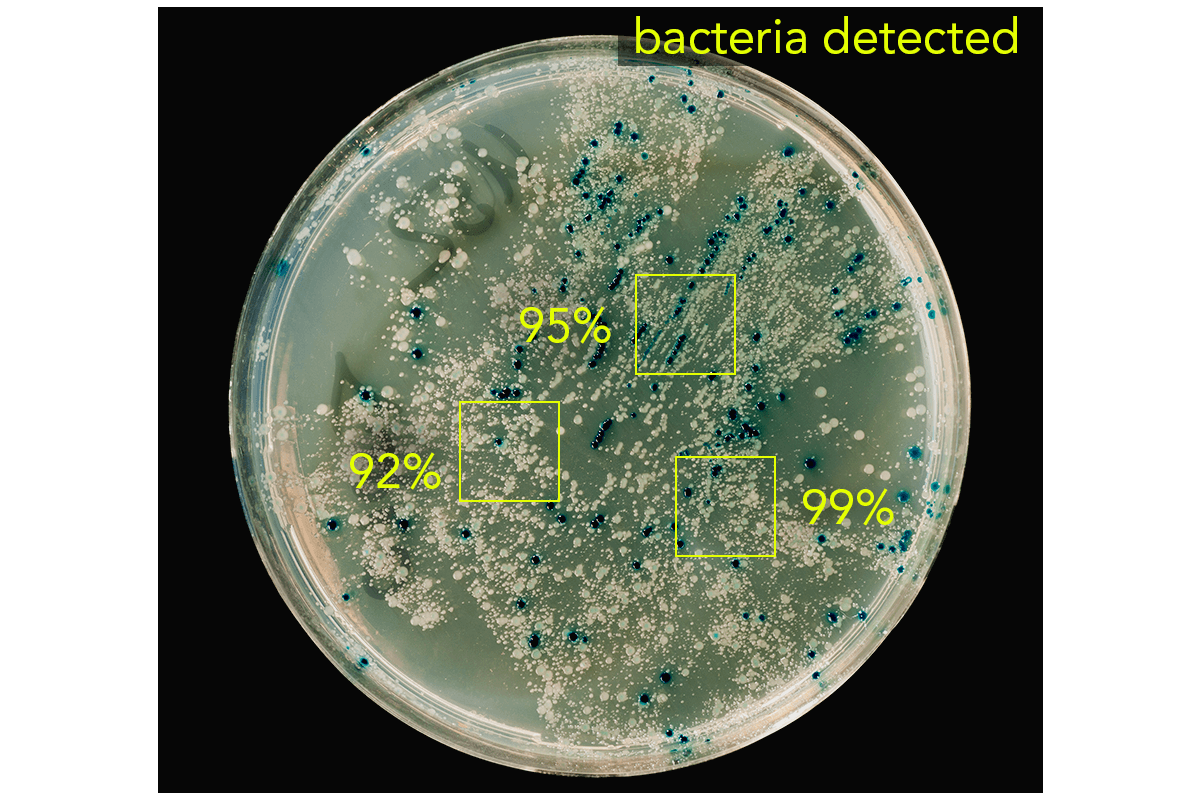

One of the Stages of this workflow orchestration & automation is bacteria detection with the help of Computer Vision and Machine learning.

You can read about this project here in more detail. Here, we will only summarize the whole idea: “Generally speaking, bacteria/viruses identification & detection was automated by Softengi to reach 99% accuracy. We created and trained a supervised machine-learning model to reach these results. The fact that the model is constantly updating with the new data that is fed into it is one of the key advantages of CV/ML for bacteria detection.”

To make the model work, we chose TensorFlow, Open CV, and Keras, as these are the most robust and effective tools for image recognition. Image recognition is just one of the multiple advantages of Machine Learning that we used extensively to reach our goal. However, MicroTechnix uses the “4 eyes” model, which means that in order to reach maximum accuracy, all the results received from AI are still counter-checked by people.

Conclusion

Creating a lab automation and orchestration process for MicroTechnix we helped the company to reduce the operational time and reduce the number of possible human-made errors. The automation of repetitive tasks made it possible for many employees to work on more creative tasks.

PEOPLE ALSO READ

AI-Powered Permit Analyzer for Regulatory Compliance

Softengi developed an AI application that streamlines the review of complex permit documents.

Universal Data Lake Publishing Service for Large-Scale Data Publishing

Softengi successfully implemented a data lake publishing solution that addresses EHS vendor's critical data transfer challenges.

Mental Well-Being Clinic for Virryhealth

Softengi developed a virtual clinic with interactive and non-interactive activities where visitors could schedule therapy sessions with medical experts and visit a VR chat in the metaverse to interact with the amazing nature and animals of the African savanna.